GK001D Terminal series use high quality brass raw material,has the characteristics of high-current- carrying capacity, convenient-wiring and durable quality.With acid-pickling treatment, products are not easily oxidized.Due to Precisely manufacturing, it avoid the difficultyof reinstallation after many times . From mold design to material processing, from parts manufacturing to product assembly, we strictly control every process.

Products Description

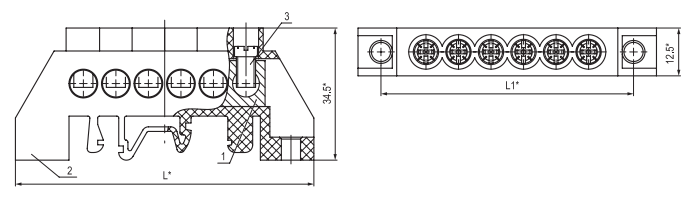

| Pole No. | Installation Dimension(mm) | Outline Dimension(mm) | Sectioncross of Brass(mm2) |

| 6 | 64.5 | 76.8*12.3 | 8*12 |

| 8 | 80 | 94.4*12.3 | 8*12 |

| 10 | 98.3 | 110.8*12.3 | 8*12 |

| 12 | 115.5 | 127.6*12.3 | 8*12 |

| 14 | 132.3 | 144.6*12.3 | 8*12 |

| 16 | 150.7 | 163*12.3 | 8*12 |

Requirements to a terminal body

1 The terminal body is manufactured from copper-zinc alloy

2 The terminal body is to be manufactured in parallelepipedal shape with mutually perpendicular side planes. Deviation of perpendicularity is no less than 0,1mm

3 The other sharp edges are to be blunted

4 The surface of holes for wire mounting is to be smooth without burrs, edge fins and etc.

5 The form of thread into threaded openings is to be full without edge fins. Every opening is to have no less than three full turns of a thread

Requirements to a terminal

1 The terminal is to be equipped with screws in the quantity equal to the quantity of contact groups for the wire fixing

2 The screws are not to create troubles to next screws at the operation

3 Dimensions and completed set of terminals are to correspond to design documents.

4 Operation temperature range could be from minus 40 to plus 50 °С.

Outgoing inspection

Visual Check:

- Bring out the absence of outer damages, deep scratches, cracks, chips, corrosion on the terminal and screws.

- All screws are to be entirely tightened.

Temperature Rise Test :

- 5% of the batch of each standard size, but not less than 10 pcs.

Flame Retardant Test:

- 5% of the batch of each standard size, but not less than 10 pcs.

Certifications:

CE, can be of ROHS at your decision

FAQ

Why should we choose Gaoke products?

A: Gaoke is a leading manufacture in the field of terminal blocks, connecting bars, din rail and copper accessories. We also provide customized solutions to meet various demands.

How can we ensure product quality from Gaoke?

A: Gaoke believes QUALITY is critical. We committed ISO9001 from paper to real work in each position in the company. From raw material supplier audits, incoming material inspection to quality control and final packing Every step is executed strictly to assure our product quality.

How long is the lead time?

A: Any order less than 500000 pieces can be completed in 30days.

Copyright © YueQing GaoKe Environmental Electric Co., Ltd. All Rights Reserved | Sitemap | Powered by