The advantages and implementation standards of wiring terminals

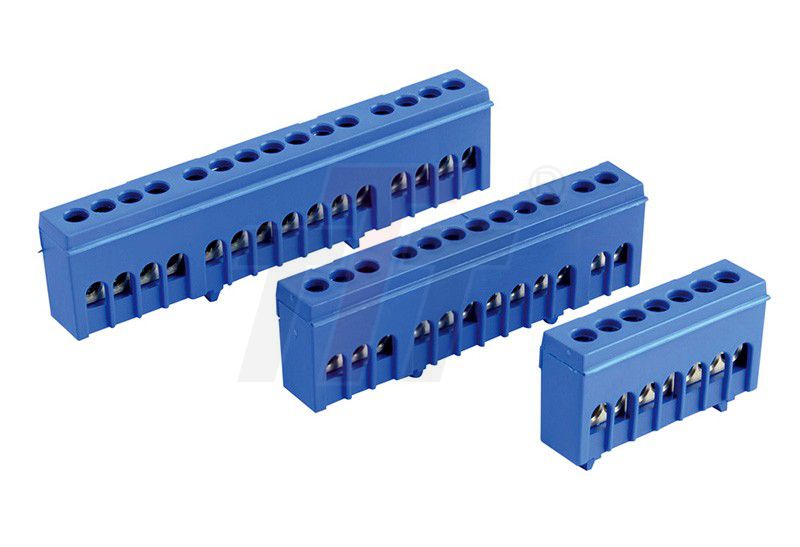

The terminal block is an important supporting component of the system engineering, from the system, subsystem, cabinet, combination, printed board to each replaceable each independent unit, tens of thousands of terminal as the human nervous system distribution in each system and parts, responsible for the control system of electric energy transmission and signal control and transmission. So this determines the application of terminals everywhere, as long as the need for wiring there will be terminals.

Execution standard of terminal blocks:

Because of the importance of terminals, terminals must be designed and used in accordance with the relevant safety and environmental standards. Only in line with the standard, to buy at ease, with peace of mind, in order to avoid the hidden danger of safety accidents. General terminal manufacturers in the design and finalization of the product is the implementation of GB/T 5095-1997 electronic equipment with electromechanical components (basic test procedures and measurement methods) :UL486E,UL1059.

No matter what type of connection the terminal block has, they have the following advantages:

1. Large wiring capacity, can adapt to various wiring requirements.

2. Mechanical decoupling of the wire clip frame and the welding needle, that is, because the wire clip frame and the welding needle are not connected as one, the torque when tightening the screw will not be transferred to the solder joint.

3. The welding needle is four-prism, and the end of it shrinks and becomes fine. The contact area is increased when the welding hole is inserted. Soldering fluid is easy to dissolve into the welding hole, not easy to weld.

4. The welding needle is made of copper alloy, which guarantees the long-term reliability of welding without dirt.

5. Tin-plated welding needle, easy to weld.

6. With heat dissipation channel.

7. The end of welding needle shrinks and becomes thin, easy to install.

As for copper terminal, it is a kind of terminal, with brass production, so called brass terminal block. Users can not only choose different parameters according to their needs, such as needle position, needle distance, but also choose different wiring directions. In practical applications, the layout of the components, such as the position of the PCB in the housing, often limits PCB terminal wiring. Printed circuit board terminals that are available in a variety of different wiring directions are of practical importance: horizontal, vertical, bevel, and front. The more options you offer, the more helpful it is to actually do it.

Printed circuit board terminals are even available for multi-layer cabling (1 to 4 layers). The arrangement between layers is very compact, and in the vertical direction of half a stitch spacing. This kind of terminal is in line with the compact layout and space - saving design needs.

The screw connection terminal can be compatible with the spring connection terminal. Compatible means they can be interchangeable without changing the layout of the printed circuit board. This makes the product much more adaptable and reduces the cost to a large extent.

If you can't find a suitable terminal, you can ask us for a custom. YueQing GaoKe is a leading manufacturer of terminals, connectors, DIN guides and copper fittings. We offer customized solutions to meet a wide range of needs.

If you can't find a suitable terminal, you can ask us for a custom. YueQing GaoKe is a leading manufacturer of terminals, connectors, DIN guides and copper fittings. We offer customized solutions to meet a wide range of needs.

We believe quality matters. We promise to guarantee the actual work of every position in the company. From raw material supplier audit, incoming material inspection, to quality control, and final packaging, every step is strictly carried out to ensure the quality of our products.

Copyright © YueQing GaoKe Environmental Electric Co., Ltd. All Rights Reserved | Sitemap | Powered by